Support

Our company will provide you with full support from the moment of production to the requalification of the cylinders. We will train your staff in the safe and quality service of composite cylinders. We will carry out a technical examination and practically help to solve the problems you are facing.

HPC Research strictly follows internationally recognised standards and regulations. All LPG cylinders leaving factory are properly tested and check for conformity to the mentioned standards by certified quality engineers of in-house inspection service.

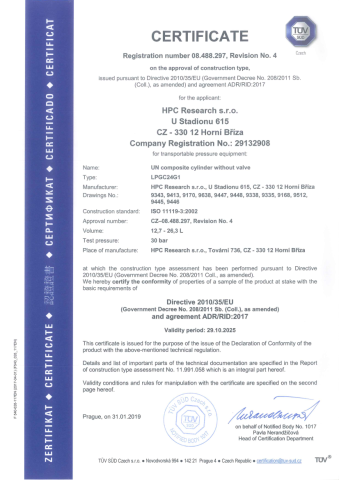

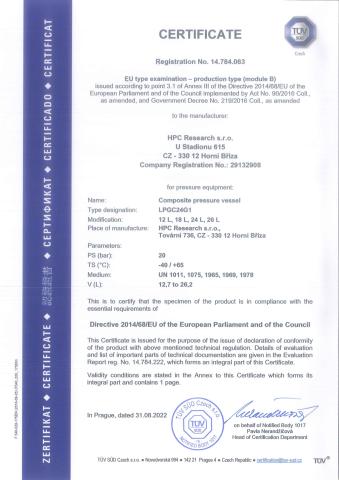

HPC Research is certified and continuously supervised by TUV SUD Czech notified body. In-house inspection service undergoes regular audits from the notified body.

Instructions & Technical Information

In this section you can find basic technical instructions and technical specifications of our products. In case you need more information don't hesitate to contact us.

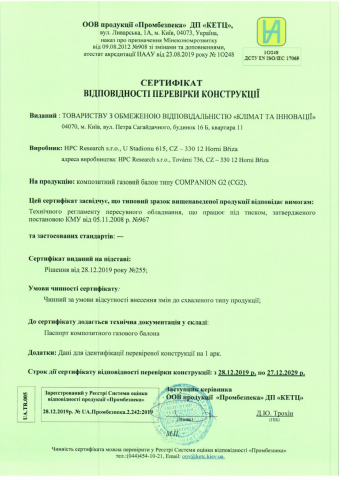

Certificates

Design of cylinders is certified according to the following standards and regulations: ISO 11119-3, EN 14427, IS 70, PED and ADR.